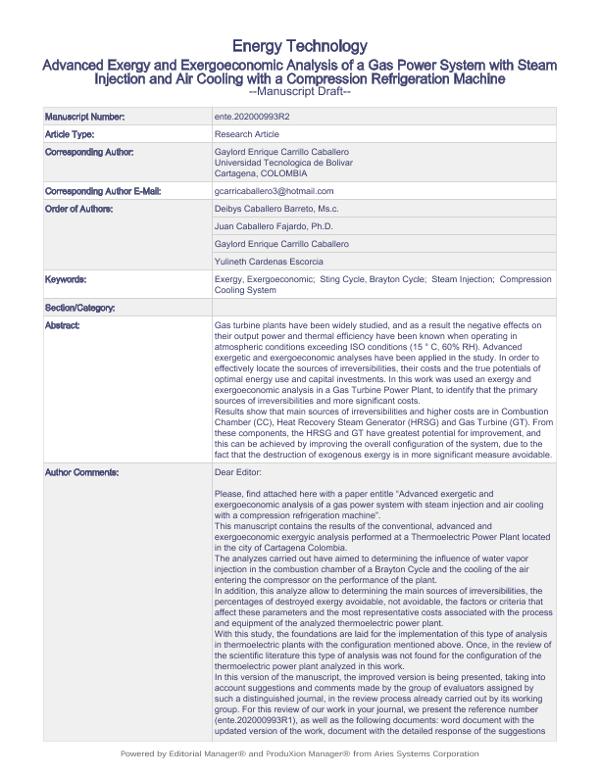

Abstract

Gas turbine power plants have been widely studied, and as a result the negative effects on their output power and thermal efficiency have been known when operating in atmospheric conditions exceeding ISO conditions. For this reason, different technologies and methodologies have been implemented, aiming to increase the output power and improve the thermal efficiency. Unfortunately, the lack of operational parameters for this system limited its characterization and implementation of strategies to improve its performance. Advanced exergetic and exergoeconomic analyses have been applied to improve energy and economic performance in steam injection gas turbine (STIG) cycle power plants with air cooling with a compression refrigeration machine. Results shows that the main sources of irreversibilities and higher costs are in the Combustion Chamber (CC), Heat Recovery Steam Generator (HRSG) and Gas Turbine (GT). From these components, the components of the HRSG and GT have the greatest potential for improvement, and this can be achieved by improving the overall configuration of the system, due to the fact that the destruction of exogenous exergy is in more significant measure avoidable. While the higher costs of investment can be reduced in the Combustion Chamber and Gas Turbine.